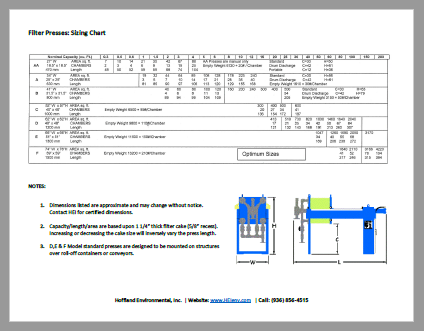

Filter Presses

> View Filter Press Sizing-Chart

Reduce Waste Volume with HEI Filter Presses

Sludge Dewatering

Slurries of waste water, such as metal hydroxides, alum sludges are pumped into the chambers of the filter press. The filtrate passes through the filter cloth and the solids are retained. The solids collect on the cloth forming an excellent filter as if one were to intentionally pre-coat the cloth. As additional solids are pumped into the chamber, the solids continue to collect until the entire chamber is full of dewatered solids. The press must then be cleaned and recycled.

Filtration

Fluids such as wine, beer, etc., may be clarified by pumping through a filter media like diatomaceous earth or cellulose filter aid. In the case of filtration, the retained solids are not important. It is the clarity of the filtrate that justifies the use of the filter press.

The filter press produces a recoverable solid such as dye stuff, or precious metals, or may be used with the intent of reducing the volume of the waste.

Reducing the volume of waste is very important for hazardous materials. A liquid slurry of hazardous metal hydroxide waste may be reduced from 40 drums of 1% solids to one drum of 40% solids. When processing hazardous waste, the filter press may economically justify itself in less than one month.

Typical Applications

- Process Filtration with Plate Washing

- Pharmaceuticals and Chemicals

- Clarification of Processed Fluids

- Municipal Sludge Dewatering

- Reduction of Waste Solids

- Precious Metal Recovery

- Biological Filtration

- Food Processing

- Saline Filtration

- Mining Products and Waste

Mining

Dewatering is accomplished by pumping sludge into chamber (A) surrounded by filter cloths (B). As pumping pressure is increased, the filtrate is forced through the accumulated filter cake (C) and cloth, leaving the chambers full of solid filter cake.

The chambers in HEI filter press are formed by two recessed plates held together under hydraulic pressure. The hydraulic ram (D) moves the follower (E) against the stack of filter plates (F) closing the press. The ram continues to apply pressure of sufficient force to counteract the high internal compaction pressures. The head stock (G) and tail stock (H) are held in place by specially engineered side rail supports bars (I).

The filtrate passes through the filter cloth and is directed by channels in the plates and drain ports (J) to the head stock for discharge. The filter cake is easily removed by simply reversing the hydraulic ram, thus opening the press. The lightweight filter press plates may then be moved apart permitting the compacted cake to fall from the chamber. The entire operation can be automated.

Construction

HEI Filter Presses are constructed of heavy duty steel or stainless steel designed to withstand up to 225 psig pumping pressure.

All structural steel is sand blasted, primed and painted with corrosion resistant epoxy paint. Internal components are constructed of high molecular weight heat stabilized chemical resistant plastic. Areas subject to wear such as the top of the side rails are covered with corrosion resistant wear plates.

Note: HEI will manufactuer a filter press for your specific application. Contact Us

Benefits

HEI Filter Presses are equipped with lightweight, corrosion-resistant polypropylene filter plates (gasketed, non-gasketed, and membrane) and can be engineered with an automatic plate spreader for easy and safe removal of compacted solids.

A self-compensating hydraulic system automatically prevents decreases in closure pressure due to thermal exposure/contraction of the chambers between the polypropylene filter plates.

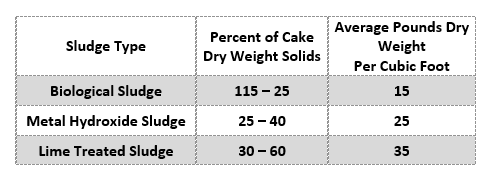

Sizing HEI Filter Presses

The HEI Filter Press will compact sludge to a dry cake having a density that is not only dependent upon the ultimate compaction pressure, but also the specific characteristics of each sludge.

The chart below gives the average dry weight of three common sludges. Use the accompanying equation to calculate the size of your filter press. First determine the quantity of sludge to be processed per cycle (minimum of 8 hours per cycle is recommended if membrane plates are utilized the pressing cycle will be reduce by 75-80%). Then insert the solids content (ppm must be divided by 1,000,000 or percent divided by 100), weight per gallon of the liquid in pounds, and pounds dry weight per cubic foot (from the chart). Complete the equation to calculate the capacity of the filter press.

The cycle time is dependent upon both the sludge dewatering characteristics and the solids content. High solids content dramatically shortens the compaction cycle. Please contact HEI for recommendations on sludge thickening equipment.

Alternative Equipment that may be added to the Filter Presses:

- Plate Spreader: Semi-Automatic pneumatic plate spreader: A carriage containing a pneumatic cylinder may be installed on the press side support bar, with air controls to engage a plate and slide it to the plate stack. The unit must be manually indexed by the operator.

- Fully Automatic Plate Spreader: A continuous chain is installed on each side of the plate with a plate shifting dog, to continuously move the plates, one at a time to the plate stack. The system is fully automatic and moves each plate in 3-7 seconds.

- Membrane Squeeze Plates: Every other intermediate plate is constructed with a flexible diaphragm behind the filter cloth. At the completion of the press filling cycle, the diaphragm is pressurized to add “squeeze” pressure to the filter cake. The squeeze diaphragm exerts pressure on the wet filter cake to drive the excess water from the filter cake and increase the density of the filter cake.

- Automatic Cloth Washing: A carriage is mounted on the press side rails with a moving spray nozzle header. The carriage automatically moves between the open plate stack, and moves the spray head up and down between the plates, washing the filter cloth.

- Automatic Drip Tray: A stainless Steel drip pan may be installed under the press to catch plate drippage and the filter cloth wash water.

- Pressurization Pump Control: The filter press slurry pump may be automatically controlled to slowly step the pump pressure up from zero to maximum pressure. This technique improves the density of the filter cake and extends the life of the filter cloth.

- Filter Press Stands: Custom built filter press stands may be installed to elevate the filter press above a filter cake shipping container.

Filter Press Sizing Chart

Click here to download / view > HEI-Filter Press Sizing-Chart